Engineering Salvation

-

Cam Plate Spindle Boss Repair

Open or Close

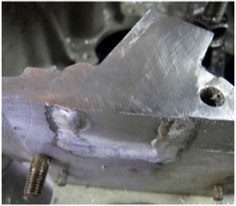

The Problem.

A common breakage on our beloved machines.

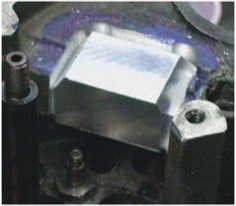

New aluminum block.

6061… much better material

than the original casting.

Removing the offending chunk

of the crankcase in preparation for

it’s replacement.

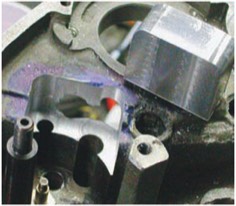

Welded in as seen from the

inner crankcase mating face.

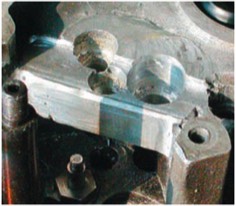

Machined to level and true

on the crankcase face.

Welded in as seen

on the top of the crankcase.

Top surface of the crankcase

machined level to the original

case dimensions.

Bore drilled, reamed, countersunk

and threaded.

Same view from the

mating crankcase’s point of view.

Material removed from the

protruding metal to give proper

exposure of the spindle end.Of course, I failed to photograph

the absolute final job after this

area was sanded, smoothed,

and overall “prettied” up.

And finally the boss ground to

provide clearance for the bevel gear. -

Front Cam Follower Spindle Bore Repair

Open or Close

This engine had suffered a malady as old as the Vincent post-war twin its self.

This engine had suffered a malady as old as the Vincent post-war twin its self.

The front cylinder exhaust cam follower spindle, the only one on the machine which relies on a threaded fit as opposed to being an interference fit as are the other three followers, can become loose in it’s bore and eat away at the female thread in the case. The best fix by far...the one that allows future use of the standard cam follower spindle...is to cut the area out, weld new material in and remachine. Beware mechanical methods of retaining the spindle used in the past such as cotter pins, etc. They will allow the spindle to loosen slightly and fret the threads. Instead, use modern retaining chemicals such as Loc-tite products.

-

Main Bearing Bore Repair

Open or Close

A tough problem, one we all hope we never have. This crankcase had been abusively “repaired” to the point that the bearing bores needed replacing.

A tough problem, one we all hope we never have. This crankcase had been abusively “repaired” to the point that the bearing bores needed replacing.

There were bronze sleeves sleeved with steel sleeves and then the bearings, none of them in proper alignment!

The “repair” was removed, the cases bored, sleeved, welded (from the inside), and remachined. The work resulted in a very satisfied customer. Please don’t trust this work to your local UJM shop or your buddy who “does some machining.”

You won’t be pleased. Certainly the owner of this very early B twin made the correct choice. And by doing so kept one of the two Phils’ early post war machines original and correct.

-

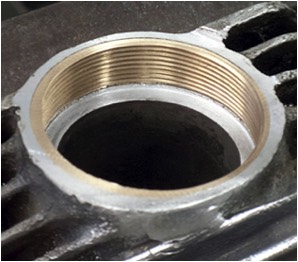

Exhaust Port Thread Repair

Open or Close There are many ways to repair stripped exhaust port threads on the Vincent, including the one you see here, performed on a bike Imported from Argentina.

There are many ways to repair stripped exhaust port threads on the Vincent, including the one you see here, performed on a bike Imported from Argentina.

The Argentines were known to be quite clever in some of their repairs. This was not one of those times.

This abuse is some of the more egregious to be seen, but the principle is more or less the same no matter the level of damage.

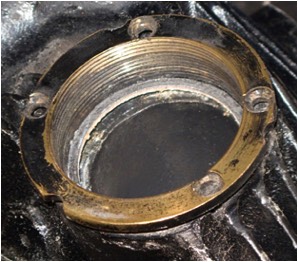

After a quick initial cleaning, one can see the amount of damage done to the port. The work begins...

Still a pretty ugly situation. The threaded holes are welded and then further fill weld added as needed to provide a base for replacement of the threads.

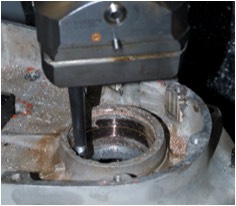

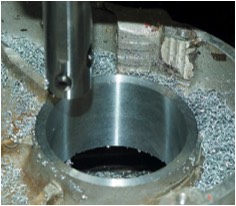

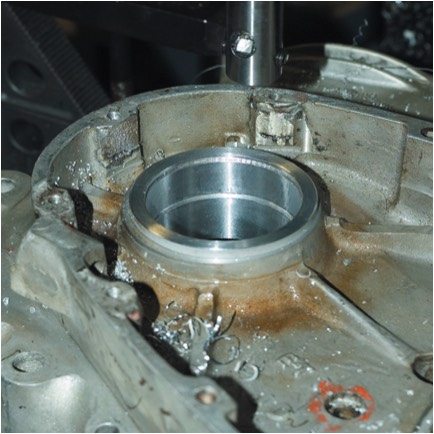

First, some passes with a boring bar to clean up the alloy that remains

in the port. With a bit more judicious filing and mill work, plus valve guides and seats, the Black Shadow head will be ready for paint and to be put back into use. The bronze threads, much stronger than those in the original aluminum casting, will last much longer and not be nearly as easily cross-threaded.

With a bit more judicious filing and mill work, plus valve guides and seats, the Black Shadow head will be ready for paint and to be put back into use. The bronze threads, much stronger than those in the original aluminum casting, will last much longer and not be nearly as easily cross-threaded. - Open or Close

Glenn Bewley